Person-In-Charge Responsibilities

During a health inspection, the inspector may ask who is the person-in-charge. That is you! The inspector may ask you to answer a few questions about the concepts in this manual. Simple questions about good hygiene and safe food handling practices that you use every day on the job.

This manual contains information about the following that may be the subject of the inspector's questions.

- Preventing Foodborne Illness

- Handwashing and Personal hygiene

- Cross contamination

- Bare Hand Contact Plan

- Exclusion and Restriction of Ill employees

- Time and Temperature Control of Foods

- Proper Cooking Temperatures

- Food Storage Methods

- Cleaning and Sanitizing (Food Contact Surfaces)

- Food Allergy Procedures

Preventing Foodborne Illness

Preventing food borne illness is primarily what food safety training is all about. Foodborne illness, sometimes called food poisoning, usually arises from improper handling, preparation, or food storage.

Foodborne illness can be caused by a large variety of toxins. However, many outbreaks and individual cases of foodborne illness result from consuming the two most common types of foodborne pathogens: Bacteria, like Salmonella, Listeria, or E. coli, or a Virus, such as norovirus or hepatitis A.

Symptoms can be mild to severe, to life-threatening illness. Common symptoms include upset stomach, abdominal cramps, nausea and vomiting, diarrhea, fever, and dehydration. Anyone can get a foodborne illness. But some people have a higher risk, such as pregnant women, young children, older people, and those with weak immune systems.

Good hygiene practices before, during, and after food preparation can reduce the chances of foodborne illness. This guide is dedicated to concepts and procedures for the prevention of food borne illness.

Handwashing

Regular hand-washing is one of the most effective defenses against the spread of foodborne illness.

Initial hand washing when you begin work, followed by hand washing at various important points as follows, is vital to avoid the spread of foodborne illness. These are:

- Before beginning work

- After using the restroom, and again in kitchen before resuming food handling

- After touching hair, face, body, or clothing

- After taking out garbage

- After sneezing or coughing

- After eating, drinking or using tobacco

- After leaving the cooking line and returning to it

- After clearing or busing tables

- After touching money

- When cooking -- after touching raw foods, and before touching "ready-to-eat" foods. More on this later.

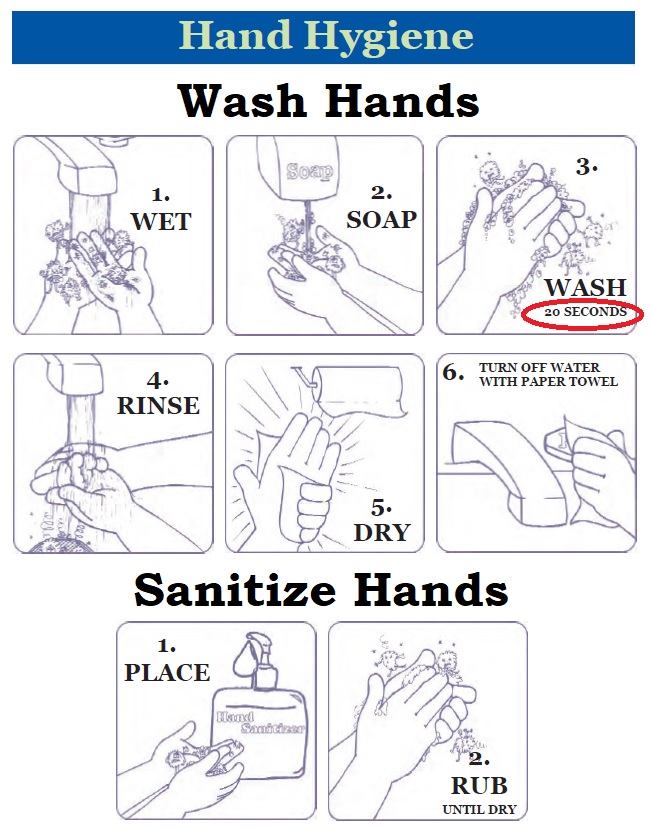

How to Wash Hands

Wash hands in the hand wash sink. If the hand wash sink is not stocked with soap, paper towels, and sanitizer, refill these items from inventory or notify your manager immediately.

IMPORTANT EMPLOYEE NOTICE

Hand Washing Video

Watch this important little video, it has more information than just how to wash hands.

Final Step - Hand Sanitizer

One thing the video didn't mention that we must apply hand sanitizer after each hand washing. A sanitizer dispenser is located by each hand washing station.

Personal Cleanliness

These personal cleanliness requirements play a major role in food safety. Failure to meet these requirement can become a source of contamination.

- Hair Restraints - Food handlers must wear a clean hat or visor.

- Clean Work Uniforms - All uniforms and aprons

should be laundered.

- Aprons - An apron must be worn when cooking

in the kitchen.

- Jewelry - Jewelry should be removed before

handling food because it can harbor germs or accidentally fall

into food. A plain wedding band is acceptable.

- Eating and Drinking - Employees should never eat or drink near food and food prep areas. Beverages must be kept out of the kitchen and out of customer view. Keep beverages on the employee break table.

- Fingernails - Food handlers must keep their fingernails trimmed, filed and maintained so the edges and surfaces are cleanable and not rough. Food employees may not wear fingernail polish or artificial fingernails.

- Cuts, wounds, sores on hands - Food handlers must completely cover the affected area with a waterproof bandage and/or single-use gloves.

Cross-Contamination

Cross-contamination is the transfer of harmful substances to food, potentially resulting in foodborne illness. One form of cross-contamination is the mishandling of ready-to-eat foods.

What are ready-to-eat foods? Ready-to-eat foods are those that will get no further cooking before consuming (an example is cooked meat); or foods that get no cooking (an example is lettuce).

Strictly speaking, the food code requires freshly washed hands inserted into food service gloves, or the use wax paper or a utensil to assure that bare hands don't touch ready-to-eat foods.

However, in our fast paced operation with near constant switching of tasks, it's impractical to put on and take off gloves over and over all shift long. So there is a provision in the food code that allows restaurants to establish a Bare-Hand Contact Plan for the safe touching of ready-to-eat foods.

Bare Hand Contact Plan (for the handling of ready-to-eat foods)

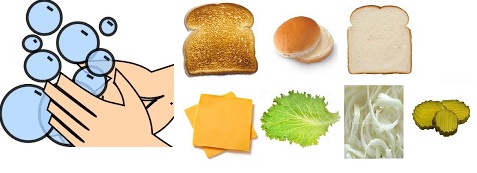

The purpose of the plan is to assure that we don't cross-contaminate when touching ready-to-eat foods with our bare hands. The plan has several control measures. The first is how to specifically handle each food item in our operation as follows:

1. Use bare hands to touch raw shell eggs, and raw griddle items such as frozen hamburger patties, steaks and bacon; or partially or precooked griddle items - hashbrowns, ham, sausage links or patties, and chicken breasts, and fryer items - french fries, fish, shrimp, and appetizers. The cooking, or cooking-to-serving-temperature process, will kill and bacteria that your bare hands might bring. |

2. Use utensils to touch cooked ready-to-eat foods. Use the food turner to remove items from the griddle such as cooked pancakes or hamburger patties. For cooked eggs, slide those from the pan onto the plate without touching them with your fingers. |

|

|

Additional Control Measures as Part of the Plan

Having the bare hand contact plan is contingent on us adhering to the plan procedure, including these additional control measures:

Wash Nails with Brush

When washing hands a nail brush is available at the hand washing sink in order to remove dirt or bacteria from underneath your finger nails. Use the brush at least at the first hand washing at the beginning of the shift.

Double Hand Washing

This simply means washing hands before leaving the restroom, and again when returning to the kitchen before resuming food handling.

Hand Sanitizer

Apply hand sanitizer after each hand washing.

Exclusion and Restriction of Ill Employees

Food handlers must notify their manager if suffering from diarrhea, vomiting, jaundice, fever, or sore throat with fever. These employees may may be excluded from work or be assigned to duties that minimize the potential for contaminating food and equipment.

You were asked to sign off on the following form during orientation.

Bare Hand Contact Plan

I

the undersigned, acknowledge that I must:

- Handle ready-to-eat foods per the company's Bare Hand Contact Plan as approved by the local heath department;

- that it is my responsibility to ensure compliance with the Bare Hand Contact Plan at all times;

- that failure of George Webb Restaurants to comply with the Bare Hand Contact Plan may result in cancellation of our Bare Hand Contact Plan;

- that continued non-compliance could result in citations, fines, loss of food license to operate, or other punitive actions.

Exclusion and Restriction of Ill Employees

Ill food employees may unintentionally spread illness if they work while ill. To protect public health, ill food employees must either be restricted from certain food handling activities or excluded from working in the food establishment.

Employees with a foodborne illness (such as salmonella, shigella, E. coli 0157:H7 or Hepatitis A) or onset of vomiting or diarrhea, must be excluded from the establishment. Employees with fever, sore throat with fever, or open/draining lesions must be excluded from working with exposed food or clean equipment, utensils, linen, and unwrapped single-service and single-use articles. If you are ill with any of the following symptoms, report to the manager:

SYMPTOMS

- Diarrhea

- Fever

- Vomiting

- Jaundice (yellowish discoloration of skin, eyes or inside of mouth)

- Sore throat with fever

- Lesions containing pus on the hand, wrist, or an exposed body part (such as boils and infected wounds, however small)

Signature _________________________________________ Date: _____________________________

Time and Temperature Control of Foods

🔍 Introduction to Time and Temperature Control

The following guide was created to explain the basics of Time and Temperature Control for Safety of (TCS) foods. It’s designed to help you understand the rules and reasons behind them—so you can handle our products safely and confidently.

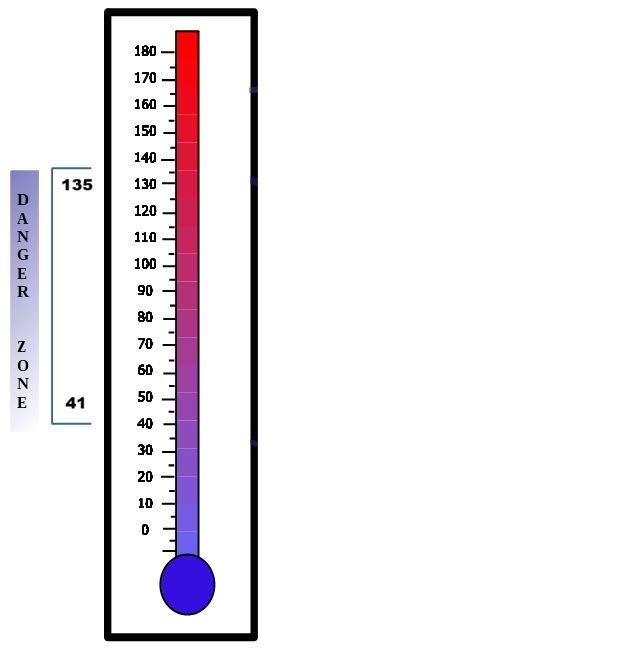

We focus on real items we use every day, like chili meat, corned beef hash, soups, and eggs, to show you how to keep food out of the Temperature Danger Zone (41°F–135°F), where bacteria grow fastest. Whether it’s thawing, reheating, hot holding, or using time as a control, we’ve built clear procedures to protect our guests and avoid waste.

Read this section carefully. It will help you work smarter and safer—and it reflects how we do things in this kitchen, not just in theory.

🚨 What’s the Danger Zone?

Bacteria grow fastest between 41°F and 135°F. This is called the Temperature Danger Zone. Food must be kept out of this range or moved through it quickly.

❄️ Cold Holding

- Keep food at 41°F or below.

- Check and log temperatures regularly.

🔥 Hot Holding

- Keep food at 135°F or above.

- Use a thermometer to verify temperature of items like chili or soup that is being heated or held under heat.

🧊 Thawing

- The best method is to thaw in the refrigerator.

Examples:

- Chili meat: Thaw in the fridge, or cook from frozen on low heat, stirring constantly.

- Steaks: Thaw in fridge or in sealed packaging under tap water for no more than 1 hour.

- Corned beef hash: Remove just long enough to portion, then refreeze immediately.

♻️ Reheating

- Reheat soup or chili to 165°F within 2 hours.

- Stir continuously while reheating and move immediately to hot holding.

❄️⏱️ Cooling

- Cool from 135°F to 70°F within 2 hours, then to 41°F within 6 hours.

- This rarely applies in daily operations, only during extended closures.

🥚 Using Time as a Control: Egg Trays

- Keep eggs in the refrigerator except between 6:00 a.m. and 12:00 p.m., you may keep one tray of eggs at room temperature for quick use.

- Label the tray with the time + 4 hours that it was removed from refrigeration (e.g., 6:00 am + 4 = 10:00 am).

- Take one tray out at a time.

- At 12:00 p.m., return any trays still within time to refrigeration and discard any past the 4-hour mark.

🛑 When in Doubt, Throw It Out

If you’re unsure how long food has been in the danger zone, discard it immediately. Safety first!

Cleaning and Sanitizing of Kitchen, Beverage Counter, and Customer Contact Surfaces

Cleaning, sanitizing, and disinfecting all surfaces that come into contact with food, beverages, or customers is essential for preventing cross-contamination and the spread of bacteria and viruses. This includes prep tables, cutting boards, grill stations, beverage counters, guest counters, and dining tables. These surfaces must be cleaned and sanitized properly throughout every shift.

Sanitizing Towels Must Be Stored When Not In Your Hand! – Use

the Red Buckets – (2 Locations)

We use two red buckets, both filled with quat-based sanitizing solution:

- 🔴 One red bucket is located under the front counter for customer and beverage area use.

- 🔴 One red bucket is located at the dish sink for kitchen and back-of-house towel use.

All clean or in-use wiping cloths must be kept in one of these red buckets unless they are actively being used.

❗ Towels must be in your hand or fully submerged in the red sanitizer bucket when not in use. They may NEVER be left on counters, prep tables, beverage stations, guest counters, or dining tables. This is a direct health code violation.

🚫 NEVER leave towels sitting out.

✅ ALWAYS keep them in your hand or return them to the red

sanitizer bucket immediately after use.

🧼 This rule helps prevent the spread of bacteria and ensures

compliance with health inspections.

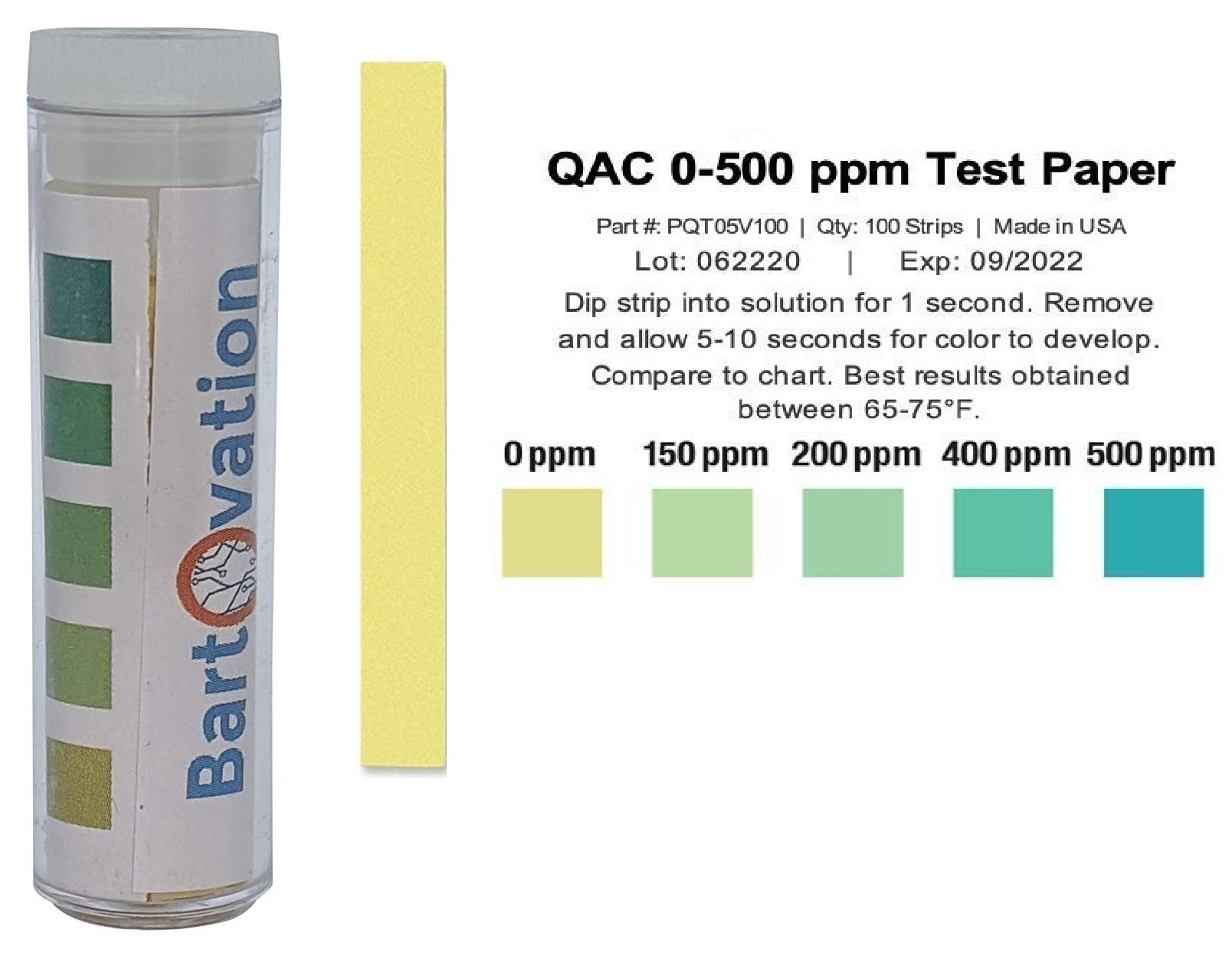

The sanitizer solution must be kept at 200–400 ppm. Replace the solution every 2 hours, or sooner if it becomes dirty or tests low.

Test the Sanitizer Solution

Use test strips during your shift to confirm that the red bucket solution is effective.

✅ Quat sanitizer must test between 200–400 ppm.

✘ If it's below range, it won’t sanitize properly—dump the red bucket and refill from dispenser.

Green Wash Bucket (Dish Sink)

The green bucket contains hot, soapy water and is located at the dish sink. It is used to wash out soiled towels before they are returned to sanitizer.

Once a towel becomes too dirty or greasy to remain in the red bucket, wash it in the green bucket before placing it back in sanitizer or hanging it for kitchen use.

Towel Usage and Conservation

Each week, a fresh stack of bar towels is delivered. This limited supply must last the entire week. Proper towel use and conservation are essential to maintaining cleanliness, passing inspections, and controlling laundry costs.

Types of Towel Use & Handling

1. Light Use – Sanitizing & Customer Areas

- Use fresh or clean towels for wiping guest-facing surfaces such as dining tables, counters, and beverage stations.

- Between uses, towels must be stored in the red sanitizing bucket to stay safe and compliant.

- If a towel looks soiled but still usable, rinse it in the green wash bucket and return it to the red bucket for sanitizing.

- When a towel becomes too dirty for customer areas, hang it on the drying bar above the linen bag to be repurposed for heavy use.

2. Heavy Use – Greasy Kitchen Areas

- Use the dried towels from above the linen bag for cleaning greasy kitchen equipment like the grill, tools, and egg station.

- Never use a fresh towel for greasy cleaning. Check the drying rack first.

- This reuse process ensures clean towels are preserved for front-of-house needs and reduces waste.

Once

a towel is no longer usable, toss it in the linen bag for

laundry pickup.

Once

a towel is no longer usable, toss it in the linen bag for

laundry pickup.

Towel Lifecycle Summary

Fresh Towel → Red Bucket (Light Use) → Green Bucket (Rinse) → Drying Rack → Heavy Use → Linen Bag

Proper Cooking Temperatures

For Food from Raw

While we typically cook these foods to temperature by appearance, such foods are safe for consumption when reaching the following temperatures:

- Hamburger 155 F

- Eggs (such as omelets) 155 F

- Chicken Tenders 155 F

- Steaks 145 F

- Fish 145 F

Food Storage Methods

First In First Out (FIFO)

When stock is put into storage it must be placed newest behind oldest. This is the FIFO method: First In, First Out method of food rotation.

Date Marking

Any ready-to-eat

potentially hazardous food must be marked with a discard date at the

time of opening or preparation. In our operation we apply a discard

date of no more than seven days for the following foods:

Any ready-to-eat

potentially hazardous food must be marked with a discard date at the

time of opening or preparation. In our operation we apply a discard

date of no more than seven days for the following foods:

Desserts: When placing desserts into the refrigerated display case, date mark each by placing a "USE BY" sticker on each wrapped piece. Add seven days to the current date.

Prep Bins: When prepping foods such as omelet mixes, French Fries and other frozen items, place a "Date Prepared" sticker on the food bin.

Food Allergy Procedures

You must have an understanding of food allergies in order to protect customers who identify that they have a food allergy and inquire about the preparation or content of our foods.

Nine (9) Major Food Allergens

Cross Contact and Allergies

As it relates to allergies, cross-contact occurs when one food comes into contact with another food and their proteins mix. One food may contain small amounts of the other food, which is often invisible. Contact may be direct (e.g. cheese on a hamburger), indirect via hands, or from utensils. Even a tiny amount of the allergenic food is enough to cause an allergic reaction in some people. Precautions must be taken to avoid cross contact as follows:

For servers: Cross contact can occur during the serving process. Unclean hands, splashed or spilled food, improperly cleaned tables, chairs, utensils, shared utensils, apron or uniform pockets.

For cooks: Shared pans, fryers, grills, counters, dishes, trays, cutting boards and utensils like knives, improperly cleaned equipment, unclean hands or gloves, spills or splattering while cooking, and removing an allergy-causing food from a meal without replacing the whole meal (such as scraping cheese from a cheeseburger instead of making a new hamburger with no cheese).

Symptoms of Allergic Reaction

- Loss of Consciousness

- Shortness of Breath

- Itching or Tingling in and around Mouth, Face, Scalp, Hands and Feet, Hives (Welts)

- Wheezing and Difficulty Breathing

- Swelling of the Face, Eyelids, Tongue, Lips, Hands, or Feet

- Tightening of the Throat (difficult swallowing)

- Sudden onset of Vomiting, Cramps, or Diarrhea

Customer Who Inform You about a Food Allergy

When a guest informs you that he or she has a food allergy you may need to inform them of ingredients in the foods they are ordering. Be understanding, listen carefully, and answer thoughtfully. If you're not sure of the ingredients it is safer to say "I don't know", and then seek the manager to find out.

If a Customer Has an Allergic Reaction

Call emergency medical services immediately. It is also important to keep the person where they are and not have them stand into an upright position.

Certification of Training

Please sign click here.

3. Use

bare hands to touch these uncooked

3. Use

bare hands to touch these uncooked